探索铅笔的奥秘:材料与制作工艺

因数本枯劳

2024-10-08 12:02:28

0次

**探索铅笔的奥秘:材料与制作工艺**

铅笔,这个看似简单的书写工具,其实蕴含着丰富的科技与工艺的秘密。它以其独特的方式记录了人类的历史,并且持续在我们的生活中扮演着不可或缺的角色。那么,让我们一同揭开铅笔的神秘面纱,深入探索其材料与制作工艺。

**一、铅笔的材料**

1. 木制外衣:大部分的铅笔是以木材为原材料,这其中包括木质心棒、防滑垫片及护杆木。木材的选择对于铅笔的耐用性和使用体验至关重要。

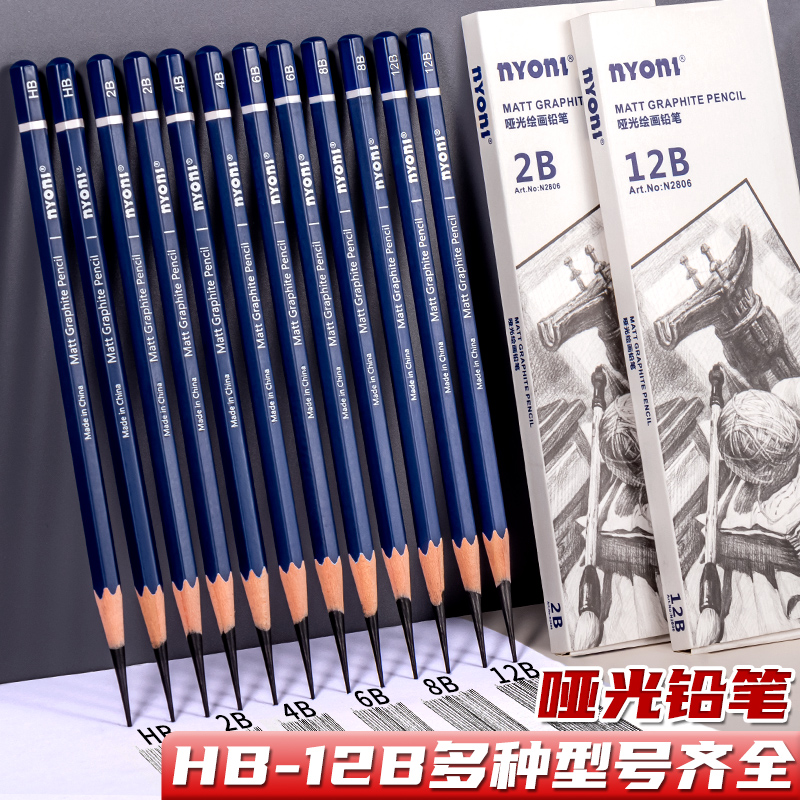

2. 铅芯:铅芯是铅笔的核心部分,负责书写。铅芯的主要成分是石墨和黏土的混合物。石墨提供顺滑的书写体验,而黏土则起到支撑和稳定的作用。

3. 漆层:许多铅笔上会有颜色涂层,通常包括红色、蓝色或黑色等。这些漆层的主要成分是各种颜色的颜料和粘合剂。

**二、制作工艺**

1. 木材加工:首先,选择合适的木材进行切割和干燥处理,以确保其具有足够的强度和耐用性。

2. 制作铅芯:将石墨粉与粘土混合均匀后,挤压成一定粗细的棒状物。这个过程需要严格控制温度和压力,以保证铅芯的质量。

3. 装配铅芯与木材:将加工好的铅芯嵌入木杆内部,并通过适当的设备进行固定和调整位置。

4. 添加漆层:在铅芯周围涂上所需的颜色涂层,这不仅可以增加铅笔的美观度,还可以起到保护铅芯的作用。

5. 削尖处理:为了使铅笔更加便于使用,通常会对铅笔进行削尖处理,使其尖端更加锋利。

**三、翻译成英文**

Exploring the Mysteries of Pencils: Materials and Manufacturing Processes

The pencil, this seemingly simple writing tool, actually contains a wealth of technological and craft secrets. It has recorded human history in a unique way and continues to play an indispensable role in our lives. Let's uncover the mystery of the pencil and explore its materials and manufacturing processes in depth.

**I. Materials of Pencils**

1. Wooden Cover: Most pencils are made of wood, including wooden core sticks, non-slip pads, and protective rods. The choice of wood is crucial for the durability and user experience of the pencil.

2. Lead Core: The lead core is the core part of the pencil for writing. The main ingredients of the lead core are a mixture of graphite and clay. Graphite provides a smooth writing experience, while clay acts as a support and stabilizing agent.

3. Paint Coating: Many pencils have color coatings, usually in red, blue, or black. The main ingredients of these coatings are various color pigments and binders.

**II. Manufacturing Processes**

1. Wood Processing: First, select suitable wood for cutting and drying to ensure sufficient strength and durability.

2. Making Lead Core: Mix graphite powder with clay evenly, and extrude it into a certain diameter stick. This process requires strict control of temperature and pressure to ensure the quality of the lead core.

3. Assembling Lead Core and Wood: Embed the processed lead core into the wooden rod, and fix and adjust its position through appropriate equipment.

4. Adding Paint Coating: Apply the required color coating around the lead core, which not only increases the aesthetic appeal of the pencil but also serves as a protective layer for the lead core.

5. Sharpening: To make the pencil more convenient to use, it is usually sharpened to make the tip more pointed and sharp.

上一篇:铅笔的历史演变与文化内涵

相关内容

热门资讯

铅笔的历史:从古至今的演变

铅笔历史可追溯至古时简易笔具,经过金属铅质笔芯、现代铅笔诞生、工业化与标准化、现代改进创新,未来将更...

铅笔品牌大比拼:哪款更适合你?

文章摘要:

本文比较了市场上多款铅笔品牌,包括经典老牌马克·法伯、专业品质的卡尔特奈尔、性价比高的...

铅笔的秘密:为何它是如此受欢迎...

铅笔因历史悠久、方便易用、轻便便携、适用广泛、成本效益高、环保无害且为艺术创作媒介等特点,成为广泛受...

铅笔的故事:从诞生到流行的演变...

铅笔的诞生与流行:从19世纪初的亨利·德雷福斯的创新到工业革命的推广,铅笔经历发展后普及并成为教育、...

铅笔在教育中的作用:为什么它仍...

铅笔在教育中的角色至关重要,其低成本、易用性、适应性强等特点使它成为实用的教育工具。铅笔独特特性有助...

铅笔品牌大比拼:哪款最适合你?

本文介绍了铅笔品牌大比拼,包括中华、马培德、三菱等品牌的特点。如何根据用途和个人喜好选择适合自己的铅...

铅笔的历史变迁与文化内涵

文章摘要:

铅笔历经历史变迁,从简单到现代,见证了人类文明的进步。它不仅是一种技术产品,还承载着教...

铅笔与钢笔的书写差异对比

铅笔与钢笔在书写体验、使用场合和持久性上有显著差异。铅笔适合草稿和修改,钢笔适合正式书写,且墨迹更持...

铅笔的多样用途:从绘画到设计

铅笔不仅用于绘画和素描,还广泛应用于写作、设计、书法、教育等领域,具有多样性和实用性。其细腻笔触和轻...

铅笔的演变:从简单工具到艺术创...

铅笔的演变史是人类文明进步的见证,从简单工具到艺术创作灵魂,体现了技术的革新。工业时代后,铅笔生产技...