铅笔制造业揭秘:生产过程中的科学与技术

怊轸嘲因

2024-11-18 18:45:10

0次

**铅笔制造业揭秘:生产过程中的科学与技术**

标题概述:

本文将带您深入探究铅笔制造业的奥秘,揭示生产过程中的科学与技术。从原材料的选择到生产工艺的精细控制,每一个环节都蕴含着丰富的科学知识和技术智慧。让我们一起揭开铅笔制造的神秘面纱,了解这一日常用品背后的科学魅力。

文章内容:

一、原材料的选择

铅笔的制造离不开木材和石墨。首先,木材的选择至关重要,通常选用质地坚硬、纹理均匀的松木或桦木作为铅笔杆的原材料。而石墨则是铅笔芯的主要成分,具有优良的书写性能和颜色表现。此外,还需要添加一些黏合剂和其他辅助材料,以增强铅笔芯的硬度和耐用性。

二、生产工艺

1. 铅笔杆加工:将选好的木材进行切割、刨削、打磨等工序,制成符合规格的铅笔杆。这一过程中,需要使用到专业的木材加工机械和精密的测量设备,确保铅笔杆的尺寸和外观达到标准。

2. 铅笔芯制造:将石墨、黏合剂和其他辅助材料按照一定比例混合,经过搅拌、研磨、干燥等工序,制成铅笔芯。这一过程需要严格控制温度、压力和时间等参数,以确保铅笔芯的质量和性能。

3. 组装与检验:将制好的铅笔芯插入铅笔杆中,通过机械或人工方式进行组装。随后进行质量检验,确保每一支铅笔都符合标准。这一环节需要检验铅笔的外观、书写性能、耐用性等方面。

三、科学技术的应用

2. 材料科学:在铅笔制造过程中,材料科学发挥着重要作用。通过研究木材和石墨等原材料的性能和特点,可以优化生产工艺和提高产品质量。此外,新材料的应用也为铅笔制造业带来了更多的可能性。

3. 环境友好型制造:为了保护环境,现代铅笔制造业逐渐采用环保材料和工艺,如使用可再生的竹材替代部分木材,减少生产过程中的污染和废弃物产生。

四、结语

通过以上介绍,我们可以看出铅笔制造业涉及到多方面的科学与技术。从原材料的选择到生产工艺的精细控制,每一个环节都需要专业的知识和技术支撑。未来,随着科技的不断进步和人们对产品质量要求的提高,铅笔制造业将会有更多的创新和发展。

**Production Process of Pencils: Science and Technology Unveiled**

Title Overview:

This article will reveal the secrets of the pencil manufacturing industry, exploring the science and technology behind the production process. From the selection of raw materials to the precise control of production techniques, each step involves rich scientific knowledge and technical wisdom. Let's uncover the mystery of pencil manufacturing and understand the scientific charm behind this daily item.

2. 材料科学:在铅笔制造过程中,材料科学发挥着重要作用。通过研究木材和石墨等原材料的性能和特点,可以优化生产工艺和提高产品质量。此外,新材料的应用也为铅笔制造业带来了更多的可能性。

3. 环境友好型制造:为了保护环境,现代铅笔制造业逐渐采用环保材料和工艺,如使用可再生的竹材替代部分木材,减少生产过程中的污染和废弃物产生。

四、结语

通过以上介绍,我们可以看出铅笔制造业涉及到多方面的科学与技术。从原材料的选择到生产工艺的精细控制,每一个环节都需要专业的知识和技术支撑。未来,随着科技的不断进步和人们对产品质量要求的提高,铅笔制造业将会有更多的创新和发展。

**Production Process of Pencils: Science and Technology Unveiled**

Title Overview:

This article will reveal the secrets of the pencil manufacturing industry, exploring the science and technology behind the production process. From the selection of raw materials to the precise control of production techniques, each step involves rich scientific knowledge and technical wisdom. Let's uncover the mystery of pencil manufacturing and understand the scientific charm behind this daily item.

Article Content:

I. Raw Material Selection

The manufacture of pencils relies on wood and graphite. Firstly, the selection of wood is crucial. Typically, hard and uniformly textured pine or birch trees are chosen as the primary material for pencil bars. Graphite is the main component of the pencil lead, providing excellent writing performance and color representation. Additionally, some adhesives and other auxiliary materials are added to enhance the hardness and durability of the pencil lead.

II. Production Process

Article Content:

I. Raw Material Selection

The manufacture of pencils relies on wood and graphite. Firstly, the selection of wood is crucial. Typically, hard and uniformly textured pine or birch trees are chosen as the primary material for pencil bars. Graphite is the main component of the pencil lead, providing excellent writing performance and color representation. Additionally, some adhesives and other auxiliary materials are added to enhance the hardness and durability of the pencil lead.

II. Production Process

1. Pencil Bar Processing: Selected wood is cut, planed, sanded, and other processes are performed to produce pencil bars that meet specifications. This process requires the use of specialized woodworking machinery and precise measuring equipment to ensure that the size and appearance of the pencil bar meet standards.

2. Pencil Lead Manufacturing: The mixture of graphite, adhesive, and other auxiliary materials is blended, ground, and dried to produce the pencil lead. This process requires strict control of parameters such as temperature, pressure, and time to ensure the quality and performance of the pencil lead.

3. Assembly and Quality Control: The manufactured pencil lead is inserted into the pencil bar through mechanical or manual assembly. Subsequently, quality checks are conducted to ensure that each pencil meets standards. This stage involves inspecting the appearance, writing performance, durability, and other aspects of the pencil.

III. Application of Science and Technology

1. Automated Production Lines: Modern pencil manufacturing adopts automated production lines, utilizing machine equipment and computer control systems to achieve automation and intelligence in the production process. This not only improves production efficiency but also reduces labor costs and error rates.

2. Materials Science: Materials science plays a crucial role in the pencil manufacturing process. By studying the properties and characteristics of raw materials such as wood and graphite, production techniques can be optimized and product quality improved. Additionally, the application of new materials brings more possibilities to the pencil manufacturing industry.

3. Environmentally Friendly Manufacturing: To protect the environment,

1. Pencil Bar Processing: Selected wood is cut, planed, sanded, and other processes are performed to produce pencil bars that meet specifications. This process requires the use of specialized woodworking machinery and precise measuring equipment to ensure that the size and appearance of the pencil bar meet standards.

2. Pencil Lead Manufacturing: The mixture of graphite, adhesive, and other auxiliary materials is blended, ground, and dried to produce the pencil lead. This process requires strict control of parameters such as temperature, pressure, and time to ensure the quality and performance of the pencil lead.

3. Assembly and Quality Control: The manufactured pencil lead is inserted into the pencil bar through mechanical or manual assembly. Subsequently, quality checks are conducted to ensure that each pencil meets standards. This stage involves inspecting the appearance, writing performance, durability, and other aspects of the pencil.

III. Application of Science and Technology

1. Automated Production Lines: Modern pencil manufacturing adopts automated production lines, utilizing machine equipment and computer control systems to achieve automation and intelligence in the production process. This not only improves production efficiency but also reduces labor costs and error rates.

2. Materials Science: Materials science plays a crucial role in the pencil manufacturing process. By studying the properties and characteristics of raw materials such as wood and graphite, production techniques can be optimized and product quality improved. Additionally, the application of new materials brings more possibilities to the pencil manufacturing industry.

3. Environmentally Friendly Manufacturing: To protect the environment,

1. 自动化生产线:现代铅笔制造业采用自动化生产线,通过机器设备和计算机控制系统实现生产过程的自动化和智能化。这不仅可以提高生产效率,还能降低人力成本和出错率。

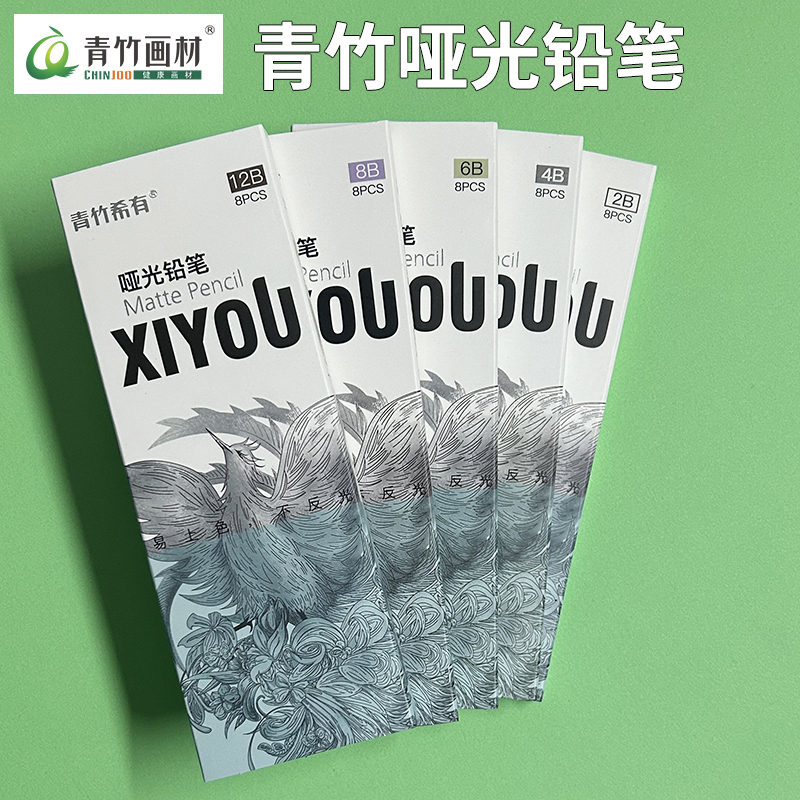

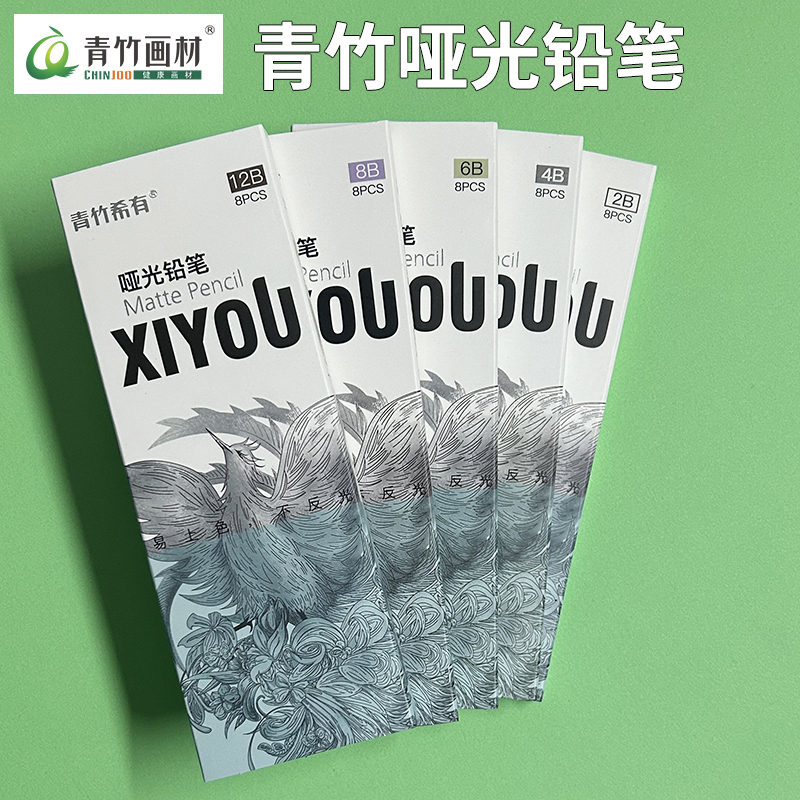

【炭笔】青竹稀有哑光铅笔素描炭笔不反光亚光铅笔美术用青竹稀有哑光铅笔售价:18.00元 领券价:18元 邮费:0.00

商家:绘伴美术品牌店 年销量:800+

【彩铅】可擦彩色铅笔24色彩铅画画专用小学生专用彩铅笔水溶性48色画笔彩色美术生专用绘画36色48色彩笔儿童初学者售价:3.90元 领券价:3.9元 邮费:0.00

商家:满帆文具旗舰店 年销量:45

【彩铅】阳光天使24色油性彩铅彩色铅笔粗笔芯原木秘密花园素描涂鸦铁盒装售价:40.00元 领券价:29元 邮费:0.00

商家:阳光天使旗舰店 年销量:1000+

上一篇:铅笔在校园生活中的作用

下一篇:没有了

相关内容

热门资讯

铅笔的历史:从古至今的演变

铅笔历史可追溯至古时简易笔具,经过金属铅质笔芯、现代铅笔诞生、工业化与标准化、现代改进创新,未来将更...

铅笔品牌大比拼:哪款更适合你?

文章摘要:

本文比较了市场上多款铅笔品牌,包括经典老牌马克·法伯、专业品质的卡尔特奈尔、性价比高的...

铅笔的秘密:为何它是如此受欢迎...

铅笔因历史悠久、方便易用、轻便便携、适用广泛、成本效益高、环保无害且为艺术创作媒介等特点,成为广泛受...

铅笔的历史变迁与文化内涵

文章摘要:

铅笔历经历史变迁,从简单到现代,见证了人类文明的进步。它不仅是一种技术产品,还承载着教...

铅笔与钢笔的书写差异对比

铅笔与钢笔在书写体验、使用场合和持久性上有显著差异。铅笔适合草稿和修改,钢笔适合正式书写,且墨迹更持...

铅笔品牌大比拼:哪款最适合你?

本文介绍了铅笔品牌大比拼,包括中华、马培德、三菱等品牌的特点。如何根据用途和个人喜好选择适合自己的铅...

铅笔的故事:从诞生到流行的演变...

铅笔的诞生与流行:从19世纪初的亨利·德雷福斯的创新到工业革命的推广,铅笔经历发展后普及并成为教育、...

铅笔在教育中的作用:为什么它仍...

铅笔在教育中的角色至关重要,其低成本、易用性、适应性强等特点使它成为实用的教育工具。铅笔独特特性有助...

铅笔的秘密:为何它如此受欢迎?

铅笔因其功能多样、轻便易携、环保可持续、价格亲民及教育用途等优势,加上文化历史意义和心理满足感,深受...

铅笔的发展史:书写工具的革新与...

铅笔发展史:从简单图形记录工具到现代多功能书写设备,见证书写工具革新与变迁。历经工业化生产、技术创新...